Have you ever faced a situation where dust attracted to the surface of plastic, rubber, glass or wooden parts is disrupting your production? If you are struggling to come up with a solution, SMC offers a proven four-pillar approach that negates static electricity issues during product cleaning.

By Ellen Parik, Training Manager Nordic & Baltic countries, SMC Estonia

By Ellen Parik, Training Manager Nordic & Baltic countries, SMC Estonia

NOVEMBER 2023

Dust attracted to component surfaces during manufacturing is problematic as it can compromise your production processes. It can impact the final appearance of your products, and even their functionality. Static charge is often the culprit, making your attempts at cleaning using conventional methods completely ineffective.

If you want to boost production performance, put an end to downtime, and maintain quality and brand reputation, SMC has the solution. We are setting out four main pillars that provide a process to ensure the highly effective cleaning of surfaces affected by static electricity: ionizing, filtration, blowing and suctioning.

Emphasising ionizing

The first pillar in our process, ionization, has a double function in surface cleaning applications. On one hand, neutralising the static charge allows easier detachment of dust particles, and on the other it prevents re-attraction of dust. Furthermore, conducting the ions to the cleaned surface with the assistance of compressed air not only supports neutralisation, it also fulfils the cleaning function by blowing dust particles away.

Selecting the optimal ionizing solution depends on various factors. For example, if we are talking about manual cleaning then an ionizer gun would be a good option. However, for an application that requires semi or full automation, a fixed system is the best solution. Of course, technical parameters like discharge speed, ion balance and potential amplitude are critical for certain applications, but in general, the size of the surface/product that requires cleaning will define the need for a more focused solution, like nozzle type ionizers, or a more widespread solution, such as bar type ionizers. Further influencing factors could be the installation space available and the need for remote control of the ionizing solution.

SMC´s Ionizer Gun – IZG10 Series. The ideal solution for manual cleaning with integrated LED light and pulse blow mode.

SMC´s Ionizer Gun – IZG10 Series. The ideal solution for manual cleaning with integrated LED light and pulse blow mode.

SMC´s Nozzle Type Ionizers – IZN10E & IZT43. Series Compact solutions for a stationary and automatic cleaning Integrated and remote-control type.

SMC´s Bar Type Ionizers – IZS & IZT40/41/42 Series. Wider coverage solutions for a stationary and automatic cleaning

SMC´s Bar Type Ionizers – IZS & IZT40/41/42 Series. Wider coverage solutions for a stationary and automatic cleaning

Integrated and remote-control type.

Filter out ineffective cleaning

The second pillar, filtration of compressed air used for blowing, is a very important but often overlooked or forgotten step. In computing terms there is a saying that fits perfectly here: garbage in, garbage out. If you introduce non-purified air, you inevitably blow impurities towards every surface you are trying to clean, wasting both time and money.

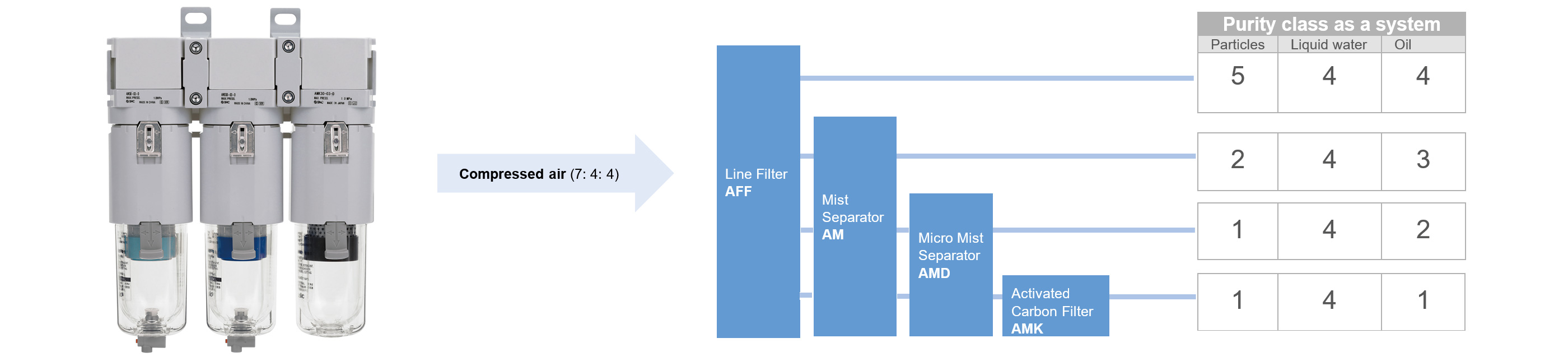

Although the minimum air purity class for ionizing solutions according to ISO 8573-1: 2010 is 2.6.3, for the cleaning solutions we recommend the use of higher classes, like 1.4.1, thus minimising the blow of the contaminants such as dust particles, compressor oil and moisture. To make an important point, the use of a single, regular filter is definitively insufficient to achieve even the minimally required purity class (2.6.3). Essentially, the necessary specified moisture level is not achievable without a dedicated dryer. Additionally, required dust particles size and oil concentration need the inclusion of at least a mist separator in addition to the main filter.

Air preparation system – SMC´s filter combination for different air purity classes.

Air preparation system – SMC´s filter combination for different air purity classes.

Blow inefficiency away

Compressed air blowing in combination with ionizing is a great way to clean product surfaces. Although ionizers use compressed air blow, to increase cleaning efficiency it can be useful to apply additional air blow nozzles. And it’s very important to use nozzles, not just some orifices, to achieve higher impact pressure and, subsequently, better cleaning effect.

SMC´s Desktop Duster Box – ZVB Series. Good example of additional air blow and dust collection integration with the static neutralization process.

SMC´s Desktop Duster Box – ZVB Series. Good example of additional air blow and dust collection integration with the static neutralization process.

SMC´s Nozzles for blowing – KN and KN-Q□A Series. Examples of nozzles for threaded connection and for easy inserting into one-touch fitting.

Another factor that supports successful surface cleaning is the choice between pulse blowing and continuous blowing. By generating pulses, you achieve a greater number of impacts, which in turn delivers better particle detachment. You also save air (and the cost to generate air) as it is not consumed between pulses. With continuous blowing there is only one impact, which would imply having to work at higher pressures to achieve better results and with higher rates of air consumption.

Instruction on suction

And finally, it’s important not only to blow away the dust, but to collect and evacuate the particles cleaned from a product using a suction system to prevent dirt from resettling on the product. If we blow but not vacuum, we are simply removing dust without any form of control.

For suctioning we recommend using vacuum flow units that provide a suction flow rate three times higher than a supplied air flow rate (the Duster Box unit, ZVB, for example, incorporates this solution). However, depending on the application, the volume of air requiring evacuation and the size of surface that needs cleaning, it’s sometimes more useful to adopt systems like high-flow pumps.

SMC´s Vacuum Flow Unit – ZHV Series

SMC´s Vacuum Flow Unit – ZHV Series

For a comprehensive approach and technical guidance on the best solution for your anti-static cleaning process SMC is here to assist you, whatever your type of application or industry. Our knowledge of the optimal technologies and techniques means we are adept at delivering a solution which negates the effects of static electricity and enhances the quality of your cleaned surfaces. As a result, you will gain from higher productivity and lower downtime, delivering a welcome boost to your OEE (Overall Equipment Effectiveness).