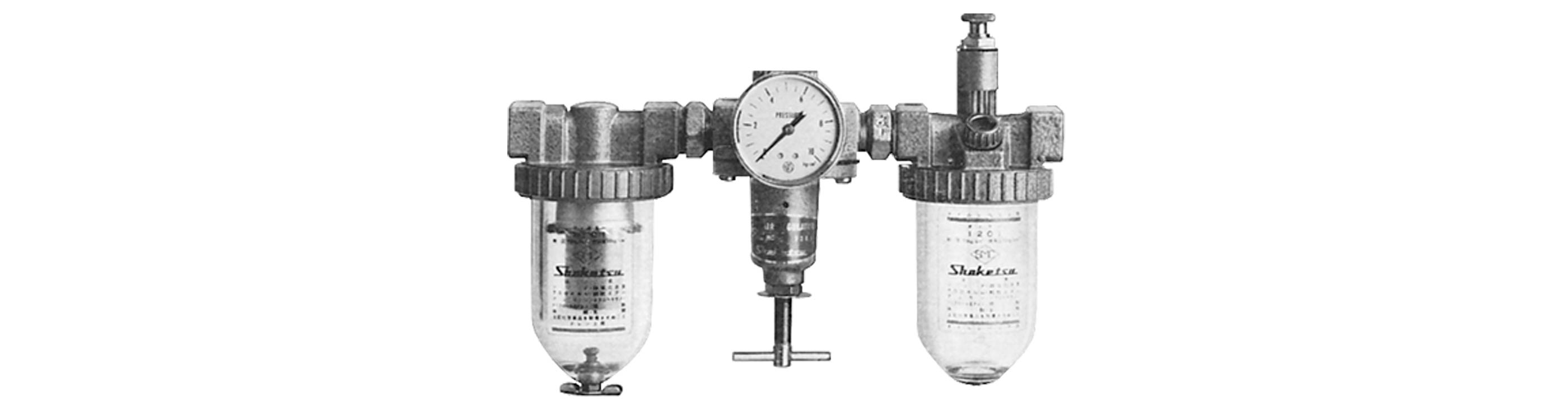

SMC was established in 1959 to manufacture and sell Sintered Metal Filter Elements. The FRL unit was first launched by SMC in 1961.

60 years of design evolution based on our customers’ requirements.

By Sean Mackenzie, Engineer, Air Equipment Section, SMC European Technical Centre

By Sean Mackenzie, Engineer, Air Equipment Section, SMC European Technical Centre

OCTOBER 2021

In pneumatics, the FRL unit is one of the key elements as they ensure the proper functioning of the rest of pneumatic equipment increasing their operating life. For us, at SMC, the FRL unit is not just key, it is the first pneumatics solution we developed. It makes sense that the worldwide leaders in pneumatics developed this as the first product. 1604, was the eligible name for this first model with the body in zinc die cast and the bowl material in AS resin. The sight glass was introduced in 1968 enabling more visible oil dropping within the lubricator. Already in the sixties, our engineers started addressing the reduction of pressure loss by introducing an auto variable throttle within the lubricator.

1970´s milestone

Already over 40 years ago, we launched the inner bowl material that is still in use today. Polycarbonate, bringing with it improved impact, chemical and temperature resistance. Back then, and until 2012 it was used for the inner bowl and then protected by a metal bowl guard. In 2012, we released to the market the double layer design. The usage of a transparent polycarbonate bowl guard provides 360° visibility, weight reduction and better resistance to rust or corrosion. All of our models ever since benefit from this.

The development launched in 1981 made every maintenance department’s day. Our customers were annoyed about the time needed to remove the bowl as it required specific tools; one touch fitting in the filter bowl was the solution provided by our engineers.

In 1983 we launched the first modular units that removed the need for threaded connections between units. This reduced the overall length of the products and allowed the integration of piping modules such as T and Cross spacers.

The modularity capabilities developed throughout the years have made it possible that today, standard FRL units can easily integrate digital pressure and flow sensors to closely monitor machine performance, and pressure relief valves to add safety measures. With this the overall capabilities of an FRL unit goes much beyond pure air treatment.

Our last solution, the AC-D series of modular FRL hit the market in 2021. It brings a modern appearance to SMC's line of air preparation equipment, while maintaining the high performance of our previous models. The performance of our filters has been measured according to ISO 12500 and the air purity class expressed according to ISO 8573-1:2010 allowing use in a broad range of applications.

Over 60 years designing, developing and meeting our customer´s fitlration needs. Over 60 years of our expertise at your disposal, coupled with an extensive range and techical support from local sales engineers. Let the worldwide leader advise you in your filtration needs.