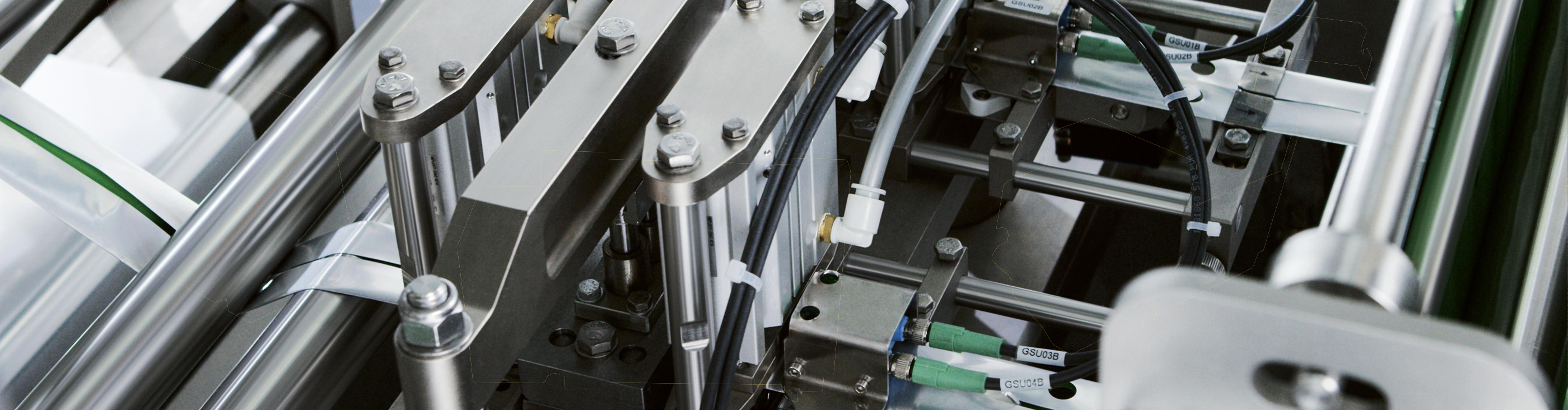

SMC valves, SY Series, used by IMA Fillshape on ERMETIKA machine

SMC valves, SY Series, used by IMA Fillshape on ERMETIKA machine

IMA Fillshape's revolutionary food pouch forming and filling machines leverage SMC solutions to boost productivity and reliability.

The flexible plastic pouches are increasingly popular with consumers around the world due to their excellent ease of use. Convenient and lightweight, they first became popular for baby food packaging, but are now widely used for a variety of other products, such as juices, sports drinks and wellness foods.

The high increase in the demand for pouch packaging is also due to major technological innovations in the field of automatic packaging machines, which have made possible to manufacture flexible packaging at a competitive cost and of impeccable quality, and which can be efficiently filled with food products, while ensuring the highest level of hygiene.

Productivity that demands reliability

The explosion in the demand for pouches coincided with IMA Fillshape’s introduction on the market of its innovative machines based on state-of-the-art automation solutions and a scrupulous focus on reliability, which prompted the Emilian company's designers to give preference to suppliers of components and subsystems sharing the same vision, among which SMC plays an important role.

Furlotti further explains: “Baby food industry has always demanded the highest level of hygienic machines, but, due to the speed required for filling the containers, the traditional solutions struggled to keep up with the rapid increase in demand. At IMA Fillshape, we have developed machines able to increase productivity by an order of magnitude, using ultra-clean, aseptic technologies coupled with an innovative continuous rotary architecture, which allows us to prepare up to 480 pouches per minute, or 8 pouches per second; and all this, while ensuring the certified quality expected in the food industry.”

The production of pouches begins with a dedicated forming machine, which creates pouches of the desired size utilizing reels of raw material. The next machine is the heart of the filling system. First, it inserts and seals the spout onto the pouch, through which the desired quantity of food product passes, then the cap is screwed in and the complete pouch is ready for the next steps of packaging and packing typical of consumer products.

The increase in the productivity of machines for continuous-cycle lines has an important impact on the reliability necessary to maintain a defect rate consistent with the requirements of very large-scale production. Therefore, the machines for forming and filling the pouches must not only be very fast, but, practically, they must also never suddenly stop.

Furlotti further explains: “The innovative technology solutions adopted on our machines control in real time everything that happens in the various filling heads. Firstly, since we utilise natural raw materials, there is an inherent variability in the product’s characteristics. For example, in case of apples, the different sugar content of each individual fruit significantly varies its density; therefore, each individual filling head must compensate for the dosage on a case-by-case basis, so that the finished product's weight is guaranteed to be always the same. In addition, full traceability of production must be ensured, and our machines allow our customers, up to the end consumer, to trace back to the individual filling and sealing head through which the pouch passed.”

Advanced automation and local support

To build its highly automated machines, IMA Fillshape employs privileged partners with whom it collaborates in the development of new solutions. One of these is SMC, which has long been a supplier of a large number of components and subsystems for the automation of the Italian company.

As confirmed by Furlotti: “By purchasing from SMC, we have the guarantee of a quality recognized by the market. SMC brand is highly appreciated by all our customers, including the worldwide availability of parts. We have not only tested the quality of the products ‘on paper’, but we have actually experienced it on a daily basis. Because our machines often work in ‘boundary’ conditions, many automation components are stressed over the entire working range allowed by the specifications, and often beyond, after confirming with the local SMC technicians how far we can go. After many years of fruitful cooperation, we have been able to see that the SMC products' technical specifications are very well defined and leave no room for interpretation, truly matching the actual behaviour of the components even under the most challenging operating conditions, something that is very important to us and not taken for granted.”

IMA Fillshape uses a lot of SMC products in its machines, from pneumatic components to traceability control systems, from chillers to PFA fittings and tubing suitable for treating and transporting aggressive fluids required by the cleaning and sterilizing systems of the machine parts coming into direct contact with the food.

“The wide-ranging catalogue of products is another of SMC’s strengths,” Furlotti adds, “and this allows us to work with a single, very reliable partner on which we can rely even during the design phase of new solutions' development. SMC's local engineers have often helped us not only to select the best solutions for our specific needs, but they have also been available to tackle together entirely new fields of use of their products.”

The challenge of sustainable mono-materials

A new trend across the entire food packaging sector is sustainability, which, in the specific field of pouch containers, leads to the use of mono-material films, which are more easily recyclable by end-users.

The mono-materials, however, have inherent characteristics that make them more difficult to process in packaging and filling machines. In particular, when heat-treated, for example when sealing the edges to form the pouch, they lengthen more than traditional materials, which complicates the process.

“Again, our advanced technology solutions and SMC's components helped a lot to make our machines perfectly compatible with the use of mono-materials”, explains Furlotti.

Detail of the IMA Fillshape KOMPAKTA machine used for making flexible pouches for the food industry

Detail of the IMA Fillshape KOMPAKTA machine used for making flexible pouches for the food industry

“Our pouch-forming machine, not by chance called ‘Kompakta’, is much more compact than the traditional solutions previously available on the market, being only 1.5 m long instead of about ten. The extremely compact nature of the mono-materials makes it easier for us to mitigate the elongation phenomena, which can thus be more effectively controlled. The compactness of the components and the wide-ranging catalogue of solutions proposed by SMC have helped us build a machine that is not only highly automated, but that takes very little space in the production facility. This is another example of how close collaboration between two companies that share a dedication to quality and technological innovation has led to successful solutions that help maintain one another’s leading position in their respective markets.”