By Sampsa Paasisalo, Product manager at SMC Automation Oy

The industrial robots of today are less expensive, more flexible and easier to program than the robots we were seeing just few years ago. However, even though this ensures more companies are now able to consider robot adoption, how is it best to achieve optimum integration among your chain of operations? Well, several options are available, with the decision often dependent on factors such as your specific application and budget.

For many tasks, traditional electrical and pneumatic motion systems are simpler to implement and less expensive. In this scenario, it is possible to combine systems in an optimal way to complete serial operations such as conveying workpieces, opening trays and so on.

Maximise creativity

Our team here at SMC provides full support for this activity. Working closely together maximises creativity, generating truly unique solutions in many instances. We provide everything from cylinders, valves, filter/separator/dryer systems, vacuum ejectors, speed controllers, fittings, rotary joints and tubing, through fieldbus systems, wireless valve systems and sensors, to card motors, end-of-arm-tools (EOAT) and EOAT changing systems. EOAT tooling includes pneumatic, electric, magnetic and non-contact grippers, as well as vacuum pads.

Image on the left: Pneumatic gripper unit for collaborative robots, JMHZ series from SMC

Right image: Vacuum gripper unit for collaborative robots, SMC series ZXP7

In all cases we adapt our solutions in line with your specific requirements, optimising common applications such as pick and place, packaging and palletising, as well as vehicle productions tasks like welding and painting.

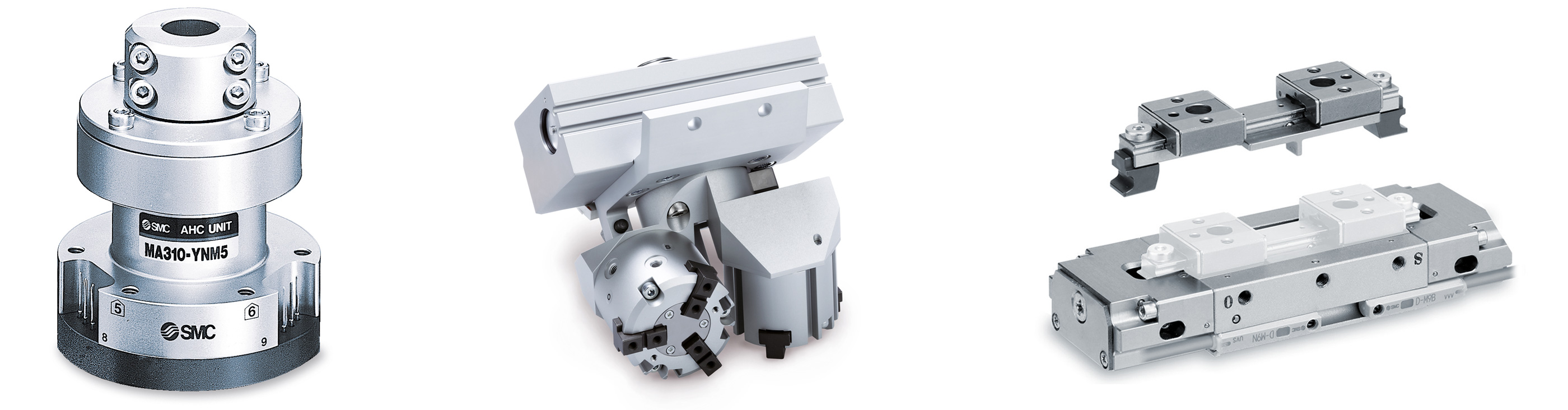

SMC´s Auto Hand Changing System – MA Series; Double Gripper Reversing Unit – MHS Series; Air Gripper with Finger Changer Function – MHF2-X7076A Series

SMC´s Auto Hand Changing System – MA Series; Double Gripper Reversing Unit – MHS Series; Air Gripper with Finger Changer Function – MHF2-X7076A Series

Move forward

Of course, there is another way to enhance the integration of your robot. Get it to move! As an approximate estimate, around 10% of manufacturing facilities adopt motion systems for their articulated arm robots. Firstly, it makes the robot’s working range far bigger, allowing it to complete a whole host of tasks, such as picking workpieces from a bin or conveyor, loading them into the work-holding device of a machine, removing it once the operation is complete, transferring the part to the next machine/workstation, and so on.

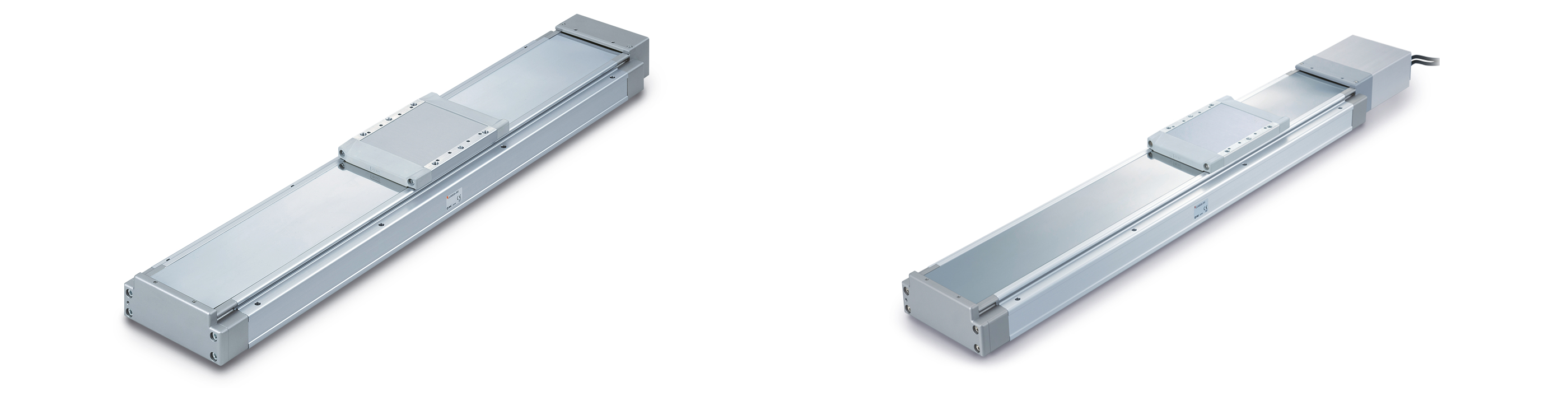

SMC Electric Actuators

Here at SMC we provide complete support in synchronising the robot and the fully integrated motion system. For instance, an electrical actuator (EA) can extend your robot’s working range when serving a CNC machine tool or storage system. In simple terms, the robot controls the movement of the EA with digital input and outputs, in this case from material supply point to CNC machine and material drop point. The component list is therefore short: robot and EA with 24 VDC digital I/O controller. Of course this solution is also possible using a fieldbus system such as PROFINET.

Whether the requirement is providing a motion system for your robot, or simply optimising your gripping or vacuum handling capabilities, SMC is able to integrate your robot into a fully automated chain. Just like your robot, all you need to do is reach out.