Saturated cartridges can lead to:

1. Machine and process start-up failure: Flushes expel grease that can lead to breakdowns in the industrial application.

2. Pressure control failure: Excessive particle build-up can damage the regulator of the maintenance unit.

3. Condensate in the system: Moisture generally causes corrosion and machinery failure. To remove these condensates, it is important to manage the dew point.

4. Automatic drains in a continuous open state: Excessive accumulation of particles can cause automatic drains to be in a continuous open state.

5. Reduced cylinder strength: Cartridge saturation will cause an increase in pressure drop, thus reducing the force of the pneumatic actuators.

6. Reduced cylinder and valve life: Poor air quality can damage pneumatic cylinders and valves within a few months, not to mention more sensitive components such as digital flow meters. Proper compressed air preparation will extend the service life of pneumatic components.

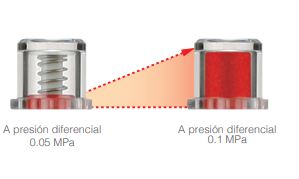

Therefore, SMC recommends replacing the cartridges every 2 years or when the pressure drop is higher than 0.1 MPa (1 Bar).

In order to check the saturation state of these filtering elements, it is advisable to carry out a periodical monitoring, which can be done, mainly, in two ways:

- With a visual indicator: It visually indicates the need to change the cartridge when the red light reaches the top.

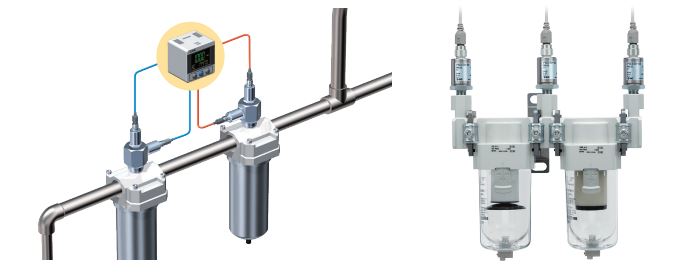

- Measuring the differential pressure: With a pressure switch at the filter inlet and one at the outlet, the pressure drop is monitored.

Preventive maintenance of the filtering elements will allow you to:

- Optimise energy consumption.

- Reduce failures in pneumatic cylinders, maintenance units and other components of the compressed air system.

- Extend the service life of machines and components.

- Avoid problems due to filter saturation.

Do you want to check the condition of your pneumatic system?

Download our pneumatic system maintenance guide: