At the heart of any production facility ecosystem is the concept of energy management, a major priority for manufacturing and process plants the world over. What’s more, with energy sustainability a growing corporate concern, there’s a real need to identify solutions that reduce your energy waste and cut carbon emissions. Among the increasingly key strategies for reducing the energy consumption of machines and processes is better compressed air management.

By Andy Still, Industry Projects Manager, Energy, Europe

By Andy Still, Industry Projects Manager, Energy, Europe

JANUARY 2024

Today, compressed air management is a digital and wireless premise. The latest decentralised digital modules support many fieldbus protocols and provide direct connection with OPC UA for open data communications, making it easier than ever to access energy savings.

And yet through astute technology selection many additional benefits become available. For instance, the challenge that many companies face right now is how to gain a more holistic view of production operations. A proven way of overcoming this challenge is to measure speed, flow, pressure, temperature and other key performance indicators (KPIs). Measuring provides data, and data provides the potential to analyse and make strategic business decisions based on this information. If you don’t measure it, you can’t improve it.

Special measures

Advanced digital compressed air management systems, such as the SMC AMS20/30/40/60, support this business function, providing the ability to measure and retrieve your digital data via various communication protocols, including EtherNet/IPTM, Profinet and EtherCAT®. Moreover, an integral direct connection to the integral OPC UA server makes it possible to bypass a PLC and send data directly to a cloud or storage system ready for processing by AI algorithms.

SMC´s Air Management System AMS20/30/40/60 Series

SMC´s Air Management System AMS20/30/40/60 Series

With the Air Management System we collect data at 10Hz, but package and transfer it via OPC UA at 1Hz. Why? Well, if you imagine a highway as a representation of the network, with each Hz representing one person in one car, it would mean having 10 cars on the road. So instead we put this into a package and transfer it at 1Hz; in essence we now have one minibus with 10 people inside to minimise highway (network) traffic.

Time to scale up

We can escalate this even further because thanks to the impressive scalability of the latest digital air management modules: it’s possible to connect up to 10 remote units to each Air Management System base unit wirelessly. To use the highway analogy again, we now have another 100 data sets (10 x 10Hz) that require transfer. To avoid 110 cars on the road with subsequent incidents due to insufficient capacity, we again package that data. We now have one very large ‘bus’ carrying 110 people without impacting on highway capacity or necessitating system expansion (and the time and cost this incurs).

The next step of digitalisation scalability is to think again of the Air Management System as a highway, but not just a highway for SMC data but anything that has the ability to transfer data via IO-Link. This capability makes the concept extremely powerful as we don’t need to build different highways to accommodate data from each manufacturer – we transfer it all on a single highway in our big bus. This is possible because each Air Management System has one spare IO-Link port on the reverse of the hub unit, allowing us to add another 10 devices to our network (highway). We thus have the ability to add a further 100 passengers to our bus, so we are now carrying 210 sets of data on our information superhighway.

Master your destiny

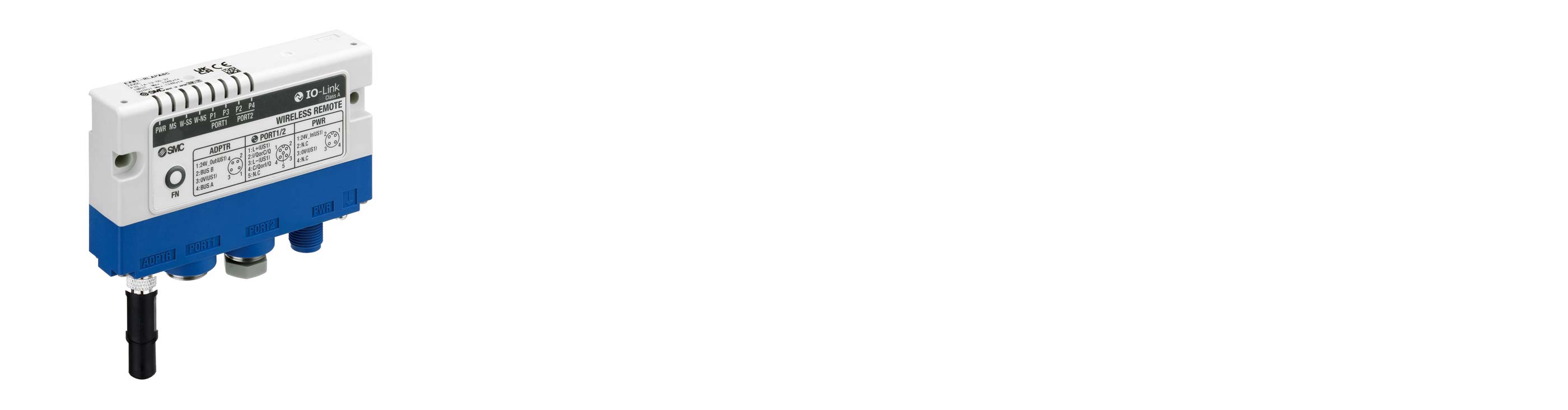

But it doesn’t end there. We can even introduce an IO-Link wireless unit (a brand new development) to the network, providing the ability to add more SMC or third-party devices and further escalate your digital architecture without cables. This capability means we are today expanding into more areas that just compressed air. Think about all the data points that can be leveraged from vibration, electricity (current transformer), water usage and other costly inputs to the process.

SMC´s Compact Wireless System, Remote IO Link Unit EXW1 RL

SMC´s Compact Wireless System, Remote IO Link Unit EXW1 RL

With the right technology choices we can now mix and match devices to collect most or all data that a factory needs to measure, and all process inputs. Most importantly, we retrieve and transfer that data via a single connection without compromising capacity or requiring additional network infrastructure upgrades to the plant: a unique market offer with a huge advantage for customers.