The design processes for BestMill, the award-winning dental CNC, have been streamlined, resulting in improved quality. BestMill stands out as the first autonomous modular device capable of simultaneously feeding two CNCs. SMC has expedited our processes by providing compact, durable and sustainable solutions, fostering collaboration and reducing design time while enhancing overall quality and efficiency.

Redon Technology is a technology company that develops high-tech devices, innovative products and software for the dental sector and has adopted the principle of added value and innovation in the products it develops. They develop technology aimed at enhancing people’s smiles, making them more beautiful and fostering happiness. Founded in 2016, Redon introduced its first product to the world in 2017. Since the beginning, Redon has been consistently accelerating its efforts with increasing momentum. The company embarked on its journey with the vision of developing “value-creating solutions” within the dental sector. In a short time, Redon has become the market leader in Turkey and has established itself as a corporate entity renowned for offering the most preferred dental CNC machines in the industry.

Furthermore, they provide faster and more precise solutions to thousands of users across over 30 countries worldwide, including Germany, Canada, England, France, Italy and the USA and promote more beautiful and healthier smiles.

Industry 4.0 and remotely communicating devices

The advent of Industry 4.0 is reshaping not only industrial sectors but also the dental market. Due to the increase in patient demands and a decrease in qualified workforce, autonomous operation of devices has started to gain importance. Consequently, there's a growing demand for smart, remotely controlled devices capable of seamless communication with other equipment.

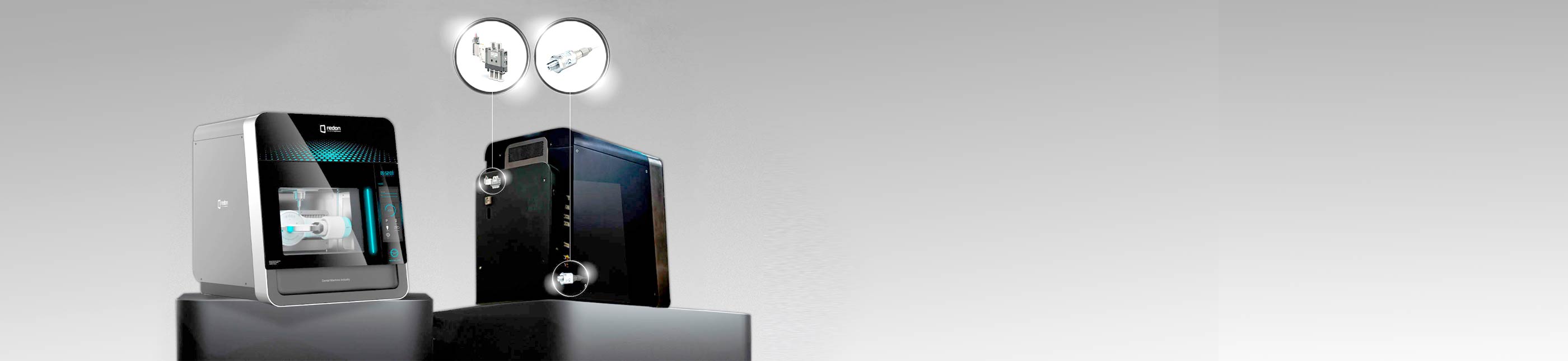

Redon Technology has responded to market needs with the introduction of their latest innovation, the Best Mill. This groundbreaking product is capable of feeding two machines using a single loading system, a world-first achievement. offering both a cost advantage and a modular system to its users.

By eliminating the need for constant and regular labour required to operate existing devices, it offers users the opportunity for long-term, autonomous operation. In the future, they aim to offer solutions where all devices can work by communicating with each other and eliminate human errors.

The award-winning Best Mill by Redon Technology

Best Mill stands out as the pioneering modular machine in the market, featuring a loader capable of simultaneously feeding products to two CNC devices at the same time. In this regard, they offer their customers and dealers a unique solution in the dental market. In addition to its functional features, like all of Redon Technology's devices, Best Mill boasts unique design elements aimed at enhancing user ergonomics and aesthetic appeal. Thanks to its loader, it provides the capability for autonomous operation 24 hours a day. This approach eliminates the need for users to wait by the machine late at night or monitor its operation continuously. Consequently, companies can enhance productivity and profitability while reducing the need for labour force. Best Mill has also received a significant response in the market as the first user-configurable dental CNC device in the world. In addition to all these technological innovations, it has been awarded in the world's most prestigious design competitions by combining its unique sensitivity and speed with an aesthetic design.

In fact, it is more important for Redon that the products and designs they develop are recognized at international standards than the awards they receive.

Support from SMC

Continuously designing or developing new products is not easy within the processes already in place. In this regard, Redon's collaborations with their product supply partners are crucial. Within the framework of these collaborations and the solutions provided, they are capable of designing and manufacturing products. By sharing new technologies with Redon, SMC accelerates their design processes and helps to improve the quality of their work. SMC Turkey team also helps to complete their projects on time and smoothly with their fast procurement process and technical support. In the past three years, product supply had become almost impossible due to the pandemic. For this reason, many factories had to stop production. In that process, SMC Turkey never left Redon in a difficult situation in terms of product supply. During this process, they never left us in a difficult situation regarding product supply within the scope of the BCP plan that SMC Turkey emphasizes. For this reason, Redon expresses their gratitude to the whole team and the company.

Process of developing solution

The process of bringing designed products to life can be quite painful. During the testing phase, we are conducting extensive trials, and encountering various issues along the way. At this point, we are holding meetings with the technical team from SMC to map out the most effective strategies for resolving the issues during the solution process. Afterwards, if a solution is provided on the current situation, they receive support on parameters. If a product change is required, the supply process is initiated and delivery is realized as soon as possible. The first trials take place in the factory environment, the next trials with partner customers. Finally, if everything is in order, the products are included in mass production.

The quality of the products ensures that Redon’s devices last longer and their service times are reduced. The compactness of some of SMC’s products gives Redon the opportunity to make devices in smaller sizes.

Why SMC?

The solution-oriented perspective and two-way communication of the SMC sales team and the qualified technical support provided by the technical team in Redon’s new/existing projects at all times, regardless of the subject matter, are valuable to them. In our opinion, all these are the reasons for priority preference.

They have devices in many different countries around the world. Service and spare parts deliveries can be time-consuming, and customs procedures can cause problems. Considering these, SMC products in Redon Technology devices globally can be replaced under warranty or service and support can be provided by working with SMC in the country where the device is located. This is how they can improve their service quality.