Such is the evolutionary rate of change in modern manufacturing that failing to keep pace with the industry’s shift to digitalisation – and its associated efficiency and productivity benefits – can prove extremely costly. But where to begin? Most professionals in this space point to data collection as the first step, because subsequent data analysis can support the adoption of predictive maintenance strategies, better decision-making and continuous process improvements. However, it is only possible to fulfil this ambition by adopting the optimal sensor for the application.

By Danilo Giordana, Energy Efficiency Project Manager, SMC Italy

By Danilo Giordana, Energy Efficiency Project Manager, SMC Italy

DECEMBER 2021

Such is the evolutionary rate of change in modern manufacturing that failing to keep pace with the industry’s shift to digitalisation – and its associated efficiency and productivity benefits – can prove extremely costly. But where to begin? Most professionals in this space point to data collection as the first step, because subsequent data analysis can support the adoption of predictive maintenance strategies, better decision-making and continuous process improvements. However, it is only possible to fulfil this ambition by adopting the optimal sensor for the application.

Pneumatic systems are widespread across a wide range of industrial machines, systems and equipment, and represent a common starting point for many digitalisation projects, offering a short return on investment. Here, three electronic sensor types are prevalent: flow, pressure and position.

As well as monitoring the consumption of compressed air, flow sensors can also check for blowing performance in applications such as cleaning, cooling, suction verification, leak test, determination of cooling status/cooling water problems (integrated temperature sensor).

SMC´s 3-Colour Display Modular Digital Flow Switch with Pressure/Temperature Sensor - PF3A8#H Series -

SMC´s 3-Colour Display Modular Digital Flow Switch with Pressure/Temperature Sensor - PF3A8#H Series -

Connectable to FRL air combination units and with integrated temperature and pressure sensor, all in one solution. IO-Link compatible.

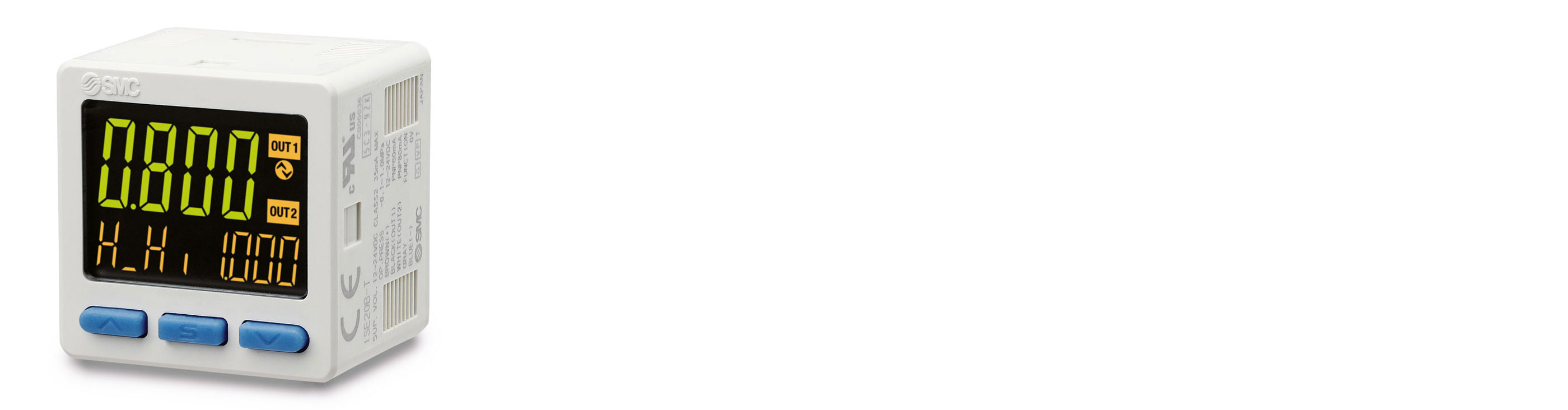

SMC´s High-Precision Digital Pressure Switch, ZSE/ISE20 Series. This switch, measures air, non-corrosive gas or general fluids. It counts with a screen that displays not only the measured value (current value) but other relevant ones (set value, hysteresis value, bottom value or peak value) at a glance. IO-Link compatible.

SMC´s High-Precision Digital Pressure Switch, ZSE/ISE20 Series. This switch, measures air, non-corrosive gas or general fluids. It counts with a screen that displays not only the measured value (current value) but other relevant ones (set value, hysteresis value, bottom value or peak value) at a glance. IO-Link compatible.

Position sensors are also important for predictive maintenance project as it will detect failure of the main critical device: the actuators. For example, position sensors can provide information about a reduction in actuator speed. Matching this speed data with flow data, it is possible to provide a quick evaluation if a given actuator needs to be replaced.

Through analysis of the data provided by sensors, machine users are able to define the machine’s ‘zero point’, namely the standard performance benchmark. From here, it becomes simple to deliver two important outcomes: understanding if something is deviating from the typical curve (and thus predicting oncoming faults as part of a targeted maintenance strategy); and identifying potential process improvements.

With the right sensors, manufacturing and process plants can take advantage of both historic and real-time data, with the latter essential to prevent ‘the unpredictable’ before it gets out of hand. After all, a minor fault often leads to a bigger and more expensive one.

SMC offers a wide portfolio of sensors, covering all customer requirements from simple on/off signal solutions to those that support IO-Link. All of the company’s sensors are simple to install and use, allowing customers to set their own parameters in accordance with the key metrics of the machine or application. If there is any doubt, SMC’s team of experts is always ready to provide advice and support.