There are certain characteristics you should seek out when selecting temperature control technology for use in the life-science sector. Arguably one of the most prevalent is a system that leverages the benefits of the Peltier effect, which introduces advantages important to those conducting laboratory work, such as high temperature stability, low noise, low vibration and compact physical dimensions.

By Kim Holy, Product Management & Industrial Application Center (IAC), SMC Germany

By Kim Holy, Product Management & Industrial Application Center (IAC), SMC Germany

MARCH 2022

For those unfamiliar with the term, the Peltier effect is the cooling of one junction and the heating of the other when electric current (DC) is maintained in a circuit of material comprising alternate layers of dissimilar semiconductors. These semiconductors are sandwiched between ceramic layers that act as thermal insulators, thus creating a Peltier cell (also known as a thermoelectric device). Notably, laboratory technicians can reverse the direction of heat flow simply by inverting the polarity of the DC current. The amount of heating/cooling generated is directly proportional to the voltage difference applied between the positive and negative power supply wires.

With a thermoelectric device you can control temperature to a narrow tolerance band (±0.01 to ±0.03°C) thanks to its very fast response time. Of course, in cooling applications there is a clear need to remove heat from the other side of the Peltier cell, which means all chiller solutions of this type require heatsinks and fans. However, the noise of the fans in a Peltier cell is lower than that produced by other existing heat-transfer technologies, ensuring their suitability for use in laboratory environments. The vibration of Peltier-based chiller systems is also extremely low because there are no moving parts (except the fans and pumps used for fluid transfer).

Sure enough, other temperature control technologies are available, such as compressor/evaporation systems, which although higher in cooling capacity, offer worse temperature stability and higher noise and vibration. Air/water or water/water passive systems can also provide high cooling capacities, but require a secondary cooling source (cold water or cold air). As a result, these systems cannot cool a fluid to a temperature lower than the ambient (air to water) or facility water (water to water).

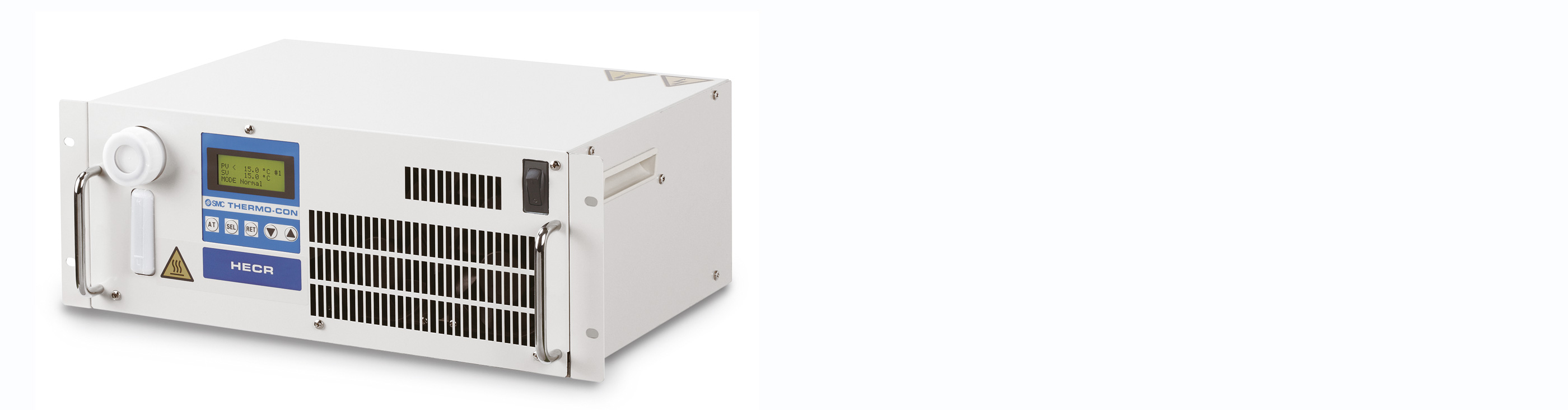

Here at SMC we provide all types of Peltier devices for life-science applications, including the HEB thermoelectric bath and the HECR thermoelectric device (air-cooled and water-cooled variants), which is mountable in a 19-inch rack.

SMC´s Thermoelectric Bath, HEB Series

SMC´s Thermoelectric Bath, HEB Series

SMC´s Thermo-con, Rack Mount, HECR Series

SMC´s Thermo-con, Rack Mount, HECR Series

As a global company that provides automation solutions for all kind of industries worldwide, we’re able to design and produce Peltier-type products for many types of high-tech applications, but especially for the life-science sector, where SMC has been a key technology partner for more than 40 years.