Although there are many bigger advantages to the adoption of industrial communications, one of the benefits you can tap into very quickly is the enablement of remote assistance. By implementing a system such as the SMC webserver, our remote teams can access your historical data and easily analyse the possible causes of your failure or malfunction. Our webserver offers short ROI for both users and machine builders as they can avoid expensive travel costs and provide an extremely reactive service.

By Massimo Gazzaniga, Technical Support Engineer Mechatronics & Network Manager, SMC Italy

By Massimo Gazzaniga, Technical Support Engineer Mechatronics & Network Manager, SMC Italy

SEPTEMBER 2022

How does it work?

Reading data via our webserver is extremely easy; you only need a standard PC with a network card. With SMC’s webserver it’s possible to read different types of data, according to whichever device is in use. Our electric actuator controllers and serial interfaces offer webserver compatibility.

What kind of data do you get?

With regard to electric actuator controllers, the most important data sets to read are those for speed and torque. Further notable requirements include the potential to change parameter settings for very fast commissioning in remote applications (via webserver) and relaying common driver alarms, such as overload.

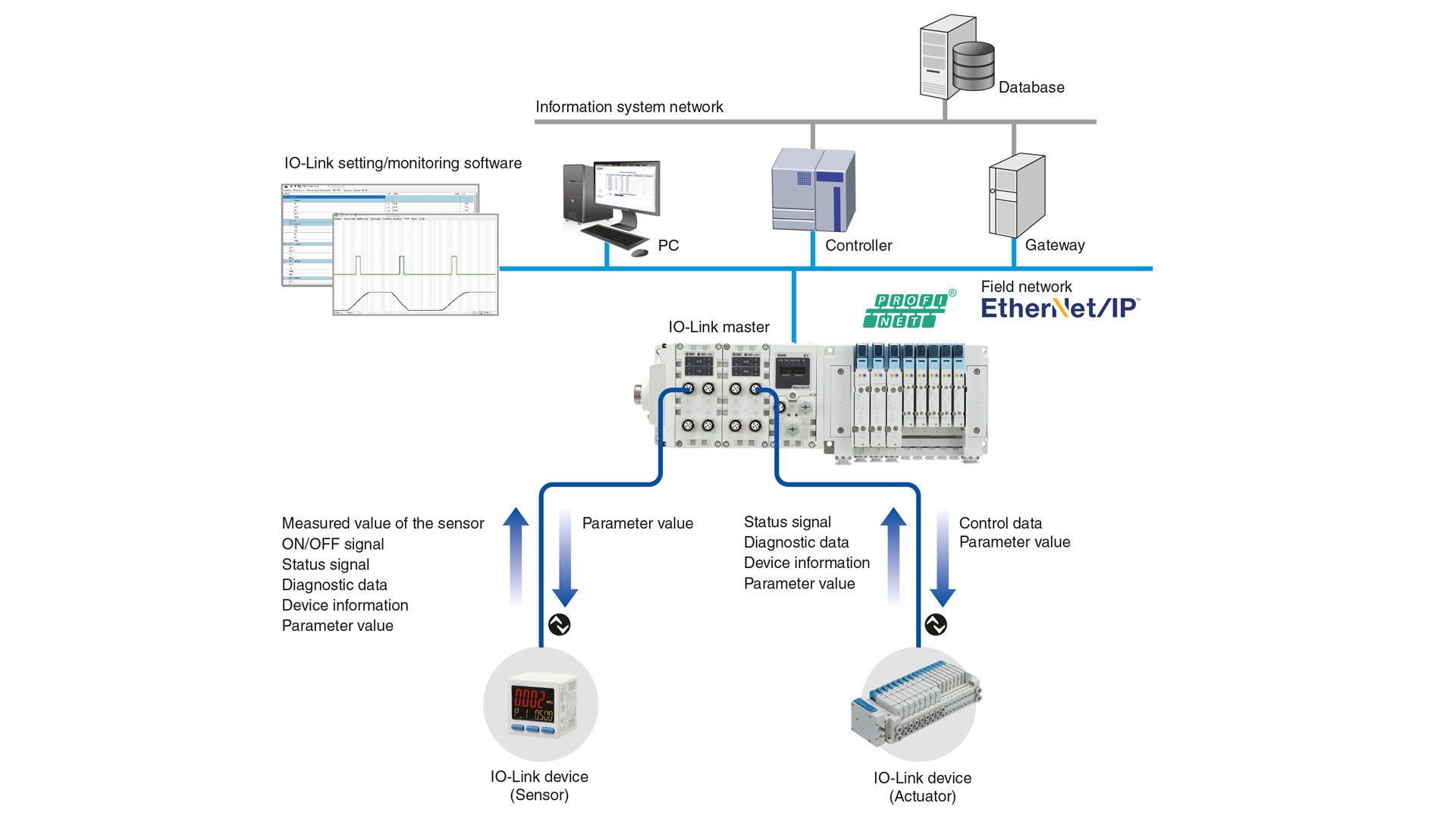

Concerning serial interfaces, the most important data to set are the range of analogue values. As a point of note, it’s possible to integrate the IO-Link master unit with our EX600 fieldbus system platform, a modular solution for reading very different types of sensors and devices. The ability to command your valves without the use of a PLC is also important.

Recreation – SMC´s IO-Link system configuration

Recreation – SMC´s IO-Link system configuration

Multiple benefits

If the right IIoT platform is in place, our devices generate a lot of data that offers a myriad of advantages for users, such as smart maintenance or energy savings. In short, any applications can benefit from our smart devices with industrial protocol communication capabilities.

As a next step, here at SMC Italia we started to use augmented reality (AR) glasses, helping the user to execute maintenance or problem-solving tasks with the help of an SMC expert. As you can see, we constantly strive to provide our customers with easy, cost-effective, added-value solutions that make a genuine difference to business operations through improved efficiencies. It’s time for us to communicate.