By Russell Breden | Group Leader, SMC´s European Technical Centre

By Russell Breden | Group Leader, SMC´s European Technical Centre

MARCH 2024

In applications such as laboratory analysis and in-vitro diagnostics (IVD) there’s growing demand for manifolds that encompass multiple circuits into one solid, transparent solution. Here at SMC, we have the capability to develop and manufacture these often technically challenging manifolds in-line with your specific application demands.

Composite manifolds are incredibly useful for many reasons, mainly because the optical clarity allows you to perform immediate visual inspection of fluid channels/paths. As a result, it’s easy for you to observe any colour changes in applications that involve fluid flow or mixing. Amalgamating all circuitry into a single manifold also means you can tap into advantages such as space minimisation and easier maintenance. Furthermore, because all of your components are in one unit, there’s significantly less requirement for tubing and fittings, thereby eliminating potential leakage points, helping with overall energy efficiency and increasing system reliability.

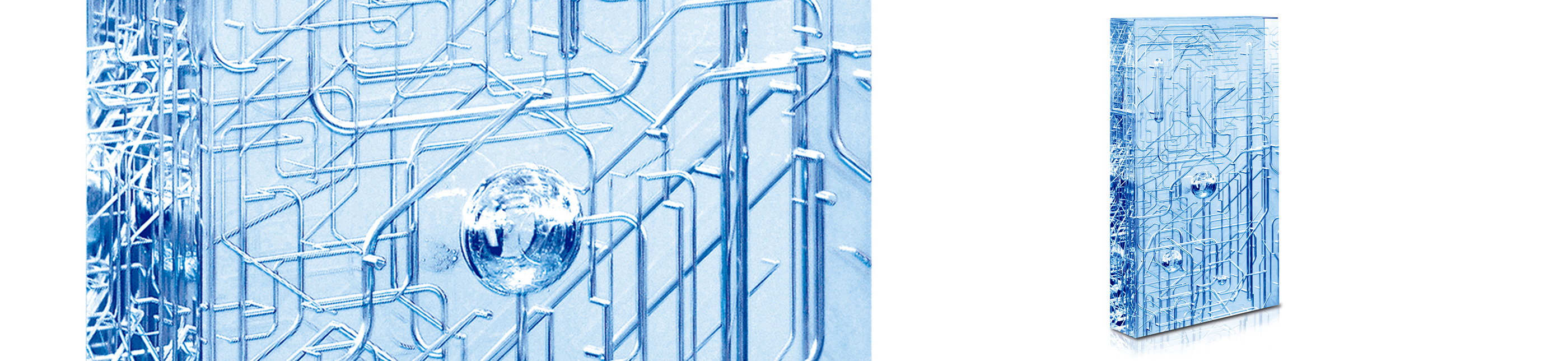

Representation of SMC´s capabilities in acrylic manifold design & development

Representation of SMC´s capabilities in acrylic manifold design & development

State of the art

The successful development and manufacture of manifolds, which often ‘fit like a glove’ means taking an artisan approach by working in close liaison with our customers, who typically provide a schematic and layout of the circuit upon which we base our design. Initial decisions often relate to material, with choices including PMMA, PC, PVC or PEI, depending largely on the type and temperature of the fluid you want to use.

Composite manifolds allow for plenty of design creativity. We can incorporate curved flow pathways (which help to minimise dead volumes), different chamber types and various flow path sizes according to your requirements. Our customers have typically benefited from mounting a variety of products including two-port valves, pressure switches, check valves and regulators, for an integrated and reliable fluidic control solution.

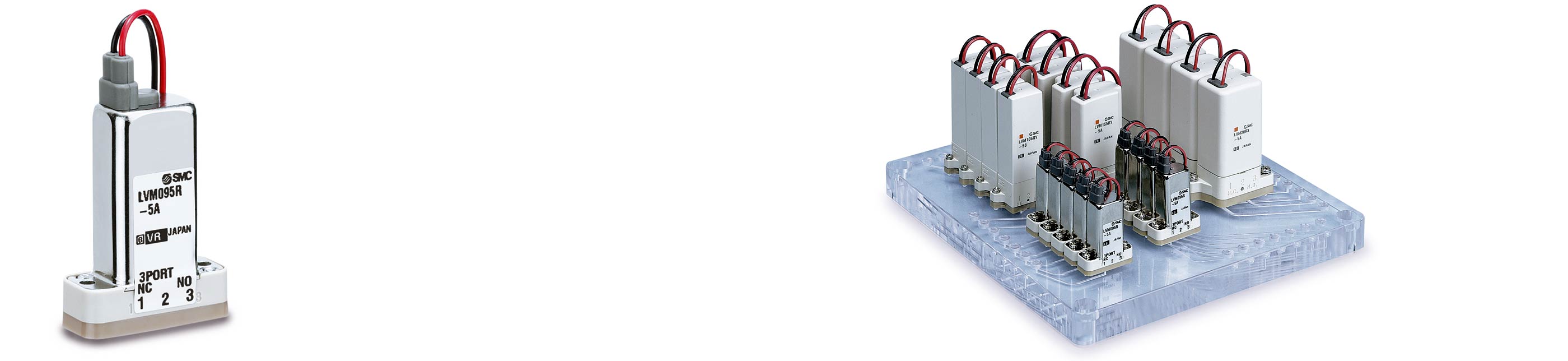

SMC´s 2/3-Port Solenoid Valve for Chemical Liquids – LVM Series

SMC´s 2/3-Port Solenoid Valve for Chemical Liquids – LVM Series

SMC´s 2/3-Port Solenoid Valve for Chemical Liquids on acrylic manifold

Our robust and proven manufacturing process relies on process expertise in machining the basic layers according to the exact fluidic path configuration agreed with customers, followed by diffusion bonding of the layers under pressure and heat for a suitably sized solution.

Final processes include the relieving of residual stresses for product stability, post-bonding machining (typically forming threads) and applying UV labels or markings for ease of use.

Medically fit

The result is a very sturdy solution that does not necessitate the use of glues or solvents, ensuring the manifold is fit for use in medical applications while simultaneously minimising fluid contamination.

If you have a fluid circuit in mind that requires a complex circuit or transparency for visual inspection, we have expert technical support available with the capability to turn your vision for a composite manifold into reality.