Depending on the series, here at SMC we rate the lifetime of our electric actuators at 5000 km or 30 million cycles without service or maintenance. There are many reasons for this performance level, including robust engineering and testing, alongside internal lubrication that is sufficient for the whole life of the actuator. However, implementing a simple yet considered maintenance schedule supports even more protection for your investment

By Gerald Rammel, Product Manager Electrical Technology, SMC Austria

By Gerald Rammel, Product Manager Electrical Technology, SMC Austria

APRIL 2023

Depending on the series, here at SMC we rate the lifetime of our electric actuators at 5000 km or 30 million cycles without service or maintenance. There are many reasons for this performance level, including robust engineering and testing, alongside internal lubrication that is sufficient for the whole life of the actuator. However, implementing a simple yet considered maintenance schedule supports even more protection for your investment.

There is no reason to doubt the longevity of your electric actuator. Tests at our headquarters in Japan showed that SMC electric actuators can reach more than twice the aforementioned official lifetime rating without maintenance. But why stop there? Sure enough, maintenance carries a cost, but this is small in comparison with investing in a replacement.

Maintenance intervals

So, how often should you maintain your electric actuator? In reality, the determination of maintenance intervals depends heavily on application-specific operating conditions such as workload, speed, overhang and contamination. For the optimal lifetime of SMC electric actuators, we recommend maintenance activities every 6 months, 1000 km or 5 million cycles, whichever occurs first.

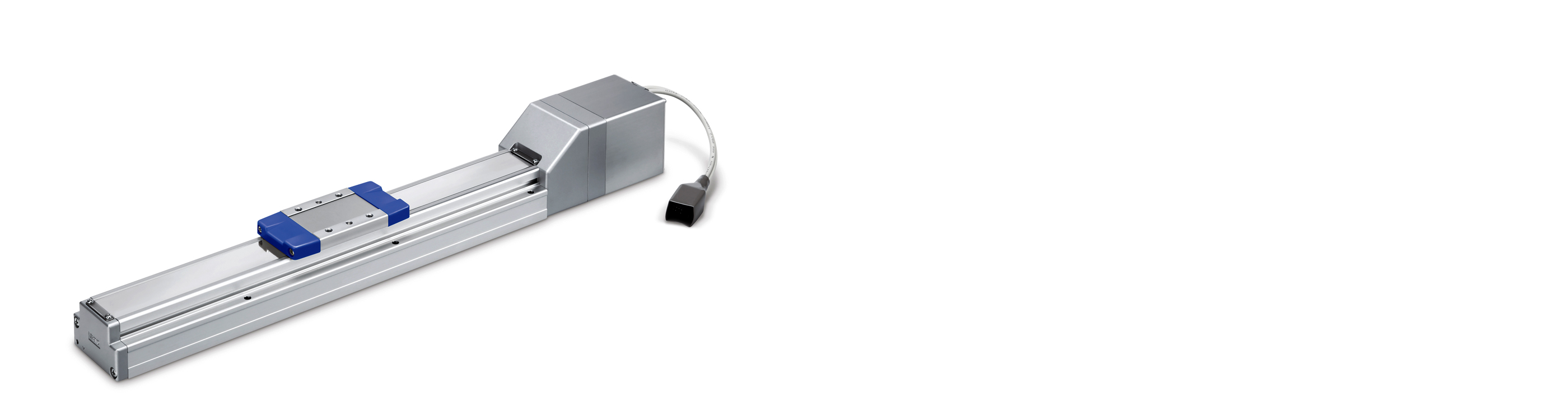

SMC´s Electric Actuator, High Rigidity and High Precision Slider Type – LEKFS Series

SMC´s Electric Actuator, High Rigidity and High Precision Slider Type – LEKFS Series

Maintenance need not be onerous; simple checks often suffice, such as visually inspecting for loose screws and loose cable connections, along with checking for any increase in vibration or noise. Further maintenance tips include checking the lubricant condition on moving parts, assessing mechanical play in fixed components, and looking for any wear or cuts on the belt.

The belt is a key component, so checking tension is also advisable. A belt that becomes loose could skip a tooth on the pulley, causing positional deviations or allowing the actuator slider to crash into the end of its stroke.

If you don’t feel confident in maintaining your electric actuator, SMC is happy to provide this service.

Selection matters

Another important part of the operating life equation is correct actuator selection. If you are not familiar with selecting electric actuators, why not use our online selection tool? Simply enter details such as the workload and speed to receive a recommendation. Alternatively, please speak directly with our experts. We are always happy to support you in choosing the right product, which in turn helps you to save money and avoid the inconvenience of installing a product that fails due to incorrect selection.

Once specified, we’re also on hand with support on setting up your electric actuator; finding the right parameters and avoiding unwanted effects such as vibration. This so-called ‘tuning’ process also has an influence on operating life. By way of example, exposing the electric motor to vibration could damage internal components like bearings.

Ultimately, electric actuators are robustly engineered products capable of delivering long service life. Nevertheless, options exist to extend this life even further, so why not provide even better protection for your investment?