Introduction

In the fiercely competitive cosmetics and personal care industries, operational efficiency and sustainability are not just advantages—they are necessities. FG Robosys, under the visionary leadership of founder and CEO Mr. Benedictus Tang, has positioned itself at the forefront of innovation in robotic bottling solutions. Based in the Netherlands with subsidiaries in Indonesia and the United States, the company has formed a strategic partnership with SMC to improve their filler machines, particularly the ROBO smartFLEX E80. This collaboration has been pivotal in reducing operational costs and environmental impact while enhancing flexibility and performance.

The challenge

In today’s landscape, end-users in the cosmetics and personal care industries are facing stricter regulations and the pressure to create a more sustainable world. This translates to a clear demand for machines that are not only energy-efficient but also capable of reducing the overall cost of ownership and minimizing CO2 emissions. These customers also require machinery that offers rapid changeovers and flexibility in adapting to various bottle types and liquids, all while maintaining high standards of quality and efficiency. Above all, the priority is on more sustainable, adaptable machines that support both environmental goals and long-term cost-effectiveness.

Customer-centric innovation

Central to FG Robosys' success is its commitment to customer-centric innovation, explains Mr Tang. By maintaining close relationships with clients, the company ensures that their feedback directly influences design enhancements and functionality improvements. This deep understanding of customer needs and market trends enables FG Robosys to develop solutions that meet specific industry requirements.

The ROBO smartFLEX E80 robotic filling system

FG Robosys flagship is the ROBO smartFLEX E80, where the E80 refers to its filling speed for cosmetic and personal care products (80 bottles per minute). With a future-proof vision, they are taking robotic bottling systems to the next level, as the company has achieved a remarkable reduction in product change-over time from over three hours to less than nine minutes. This dramatic improvement provides customers with unprecedented flexibility and efficiency, allowing them to enhance occupancy rates and adapt swiftly to changing market demands.

On top to the cost effectiveness, Mr. Tang and his team wanted to upgrade their lines with energy optimization so not only to further reduce operational cost at end users point but also to reduce the environmental impact of their machines. As a result of collaboration between FG Robosys and SMC, a milestone was reached: ROBO smartFLEX E80 is equipped with the latest in energy efficiency. SMC´s brand new air management system and the capability of working at 4 bar.

In the words of Mr. Tang, “SMC´s Air Management System is very unique to us”. The Air Management System is designed to save compressed air by automatically reducing the pressure during machine standby times. By switching to a lower pressure, the unit minimizes air consumption and reduces energy costs when machines are inactive. Additionally, the Air Management System offers a unique digital advantage: it gathers high-quality, real-time data on pressure, flow, and temperature from each machine. This data enables FG Robosys customers to monitor and analyse machine performance, optimize maintenance schedules, and even integrate insights with automated maintenance systems or AI-driven machine learning tools. According to Mr. Tang “SMC´s Air Management System is a unique product by SMC, we have implemented it in several lines, and we are very satisfied with the results”.

Integration of SMC´s Air Management System with FRL components enhances sustainability and digitalization for FG Robosys' machine

Integration of SMC´s Air Management System with FRL components enhances sustainability and digitalization for FG Robosys' machine

The integration of these technologies into the ROBO smartFLEX E80 marks a significant advancement in robotic bottling systems. Switching from a 7 bar to a 4 bar air operating pressure resulting in substantial energy savings, directly contributing to reduced operational costs and a smaller environmental footprint.

Future outlook

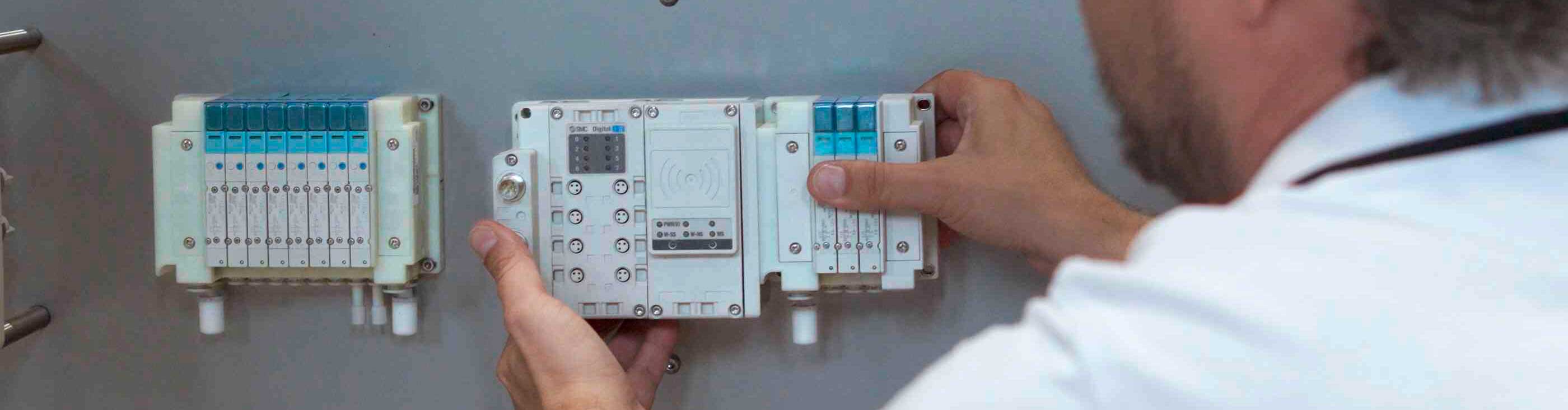

But it does not stop there. By implementing SMC’s solutions for wireless communication in the control of machine components, FG Robosys can offer even more advantages to its customers. First and foremost, this leads to a drastic reduction in labour during the assembly of the machine and a significant decrease in the amount of cabling required, which greatly simplifies the layout of the pneumatics.

Additionally, wireless communication ensures that potential damage to cables is no longer a concern, significantly reducing downtime and thereby increasing productivity. Wireless monitoring allows close tracking of machine behaviour, status, and energy consumption, providing valuable insights without the risk of data breaches, as the technology operates on a proprietary protocol. Furthermore, reduced material usage, thanks to the elimination of unnecessary components and cabling, contributes to a lower CO2 footprint for the machine. This approach emphasizes ease of use and efficiency, focusing on exactly the features the customer needs, without unnecessary complexity or over-dimensioning.

SMC's conventional valve terminal (left) compared to SMC's Wireless serial transmission system for input/output (right). SMC Wireless is a proven technology which greatly reduces wiring and labour costs.

SMC's conventional valve terminal (left) compared to SMC's Wireless serial transmission system for input/output (right). SMC Wireless is a proven technology which greatly reduces wiring and labour costs.

Conclusion

The partnership between FG Robosys and SMC exemplifies how strategic collaboration and technological innovation can effectively address industry challenges. By integrating SMC's Air Management System, adopting 4-bar pneumatic practices, and exploring wireless communication solutions within the ROBO smartFLEX E80, FG Robosys has delivered a comprehensive solution that not only meets but exceeds the demands of modern manufacturing in the cosmetics and personal care sectors. This achievement underscores their shared commitment to supporting customers' success through innovation, enhanced efficiency, and sustainability. These advancements reduce energy consumption, optimize machine efficiency, and minimize downtime. This project demonstrates how FG Robosys, in partnership with SMC, is setting new standards for efficiency and sustainability in the industry.