Refining is arguably the most important process in chocolate production as it determines the consistency and texture of the final product. We know from experience that only by using high-quality, high-performance industrial control and automation solutions, backed up with global support on a local level, will builders of chocolate refining machinery succeed in gaining market share.

By Paolo Tornavacca, Client Group Manager, SMC Italia

By Paolo Tornavacca, Client Group Manager, SMC Italia

MARCH 2022

The chocolate refining process typically consists of 3-5 large rolls mounted in a horizontal orientation containing a cold water circulation system. This water lowers any heat that develops due to friction from roller movement. Roller temperature regulation is also necessary to decrease or increase the adhesion of chocolate paste to the roller. In addition, cold water is required to cool motors and other moving mechanical elements or components.

Keep cool under pressure

SMC has extensive and proven experience in devising solutions that drive and control the water circuit in chocolate refining machinery.

Among the principal attributes of SMC products is reliability. Many chocolate factories run the refining process 24/7, so any component failures outside of the scheduled maintenance period are potentially disastrous. Increasing numbers of chocolate refining machinery manufacturers are therefore leveraging the advantages of components such as the SMC JSXD 2-port solenoid valve. Offering excellent environmental resistance due to its stainless steel coil cover (IP67 enclosure) and resin stopper construction, the JSXD provides durability and long service life. In chocolate refining, the JSXD valve will close and open the cooling water circuit and resist water hammer, all while offering a 14% reduction in power consumption compared with the previous generation product.

SMC´s JSXD 2-Port Solenoid Valve

SMC´s JSXD 2-Port Solenoid Valve

Another notable consideration is our ability to customise complete manifolds and optimise performance in line with your specific requirements. Helping to increase cooling efficiency and accelerate cycles, our customised designs also reduce overall size for use in restricted areas of the machine.

Taking the heat off

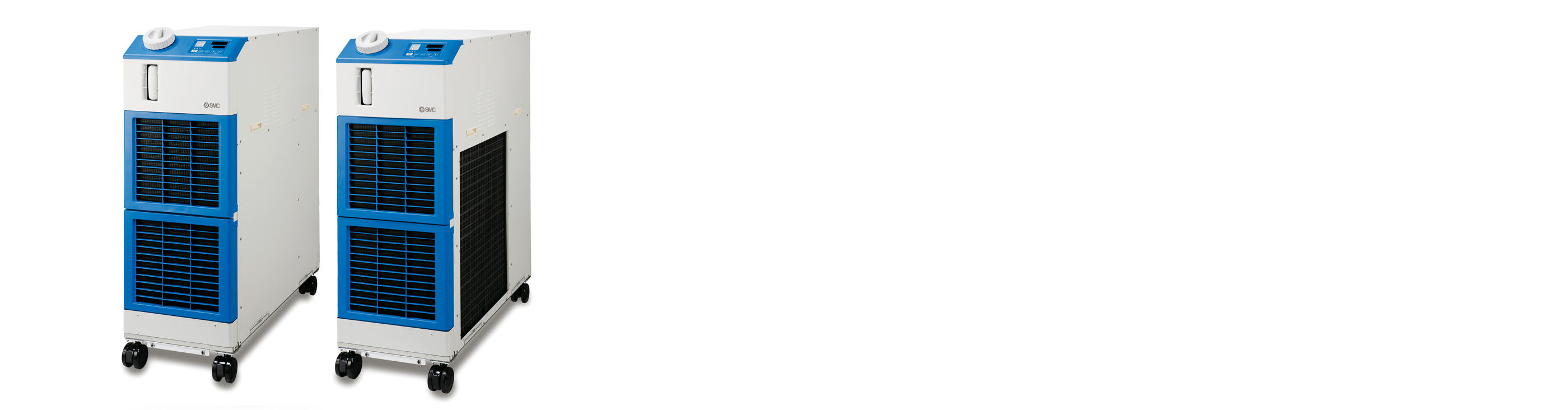

Another key SMC solution for chocolate refining is the company’s range of high-performance thermo-chillers, which refrigerate and control cooling water for the rolls between strict limits. Some machine builders produce large, centralised, home-made solutions featuring a pump, heat-exchanger, piping, valves, tank and so on. However, all of these components are replaceable with a single embedded thermo-chiller from SMC. This reduces cost, provides a single warranty solution, and simplifies machine diagnostics in the event of a fault thanks to sensors and alarms that are integral to SMC thermo-chillers.

Compact, convenient and energy-efficient, an SMC thermo-chiller such as the popular HRS/HRSH series represents a one-stop-shop solution for precise temperature stability control; yet another key asset for refining chocolate and enhancing the final texture and flavour of the product.

SMC´s HRSH Thermo-chiller – Various sizes to accommodate to your specific requirements.

SMC´s HRSH Thermo-chiller – Various sizes to accommodate to your specific requirements.

As chocolate refining has such a direct influence on product outcome, there is a clear need to specify high-performance, innovative products proven in driving and controlling the water circuit. This strategy is the best way of avoiding potential compromises to both product quality and brand reputation.